| We can supply: sunflower/rice bran/cotton seeds/soybean/ peanut/palm oil refinery machine |

| 1-10T/D Crude oil refinery machine |

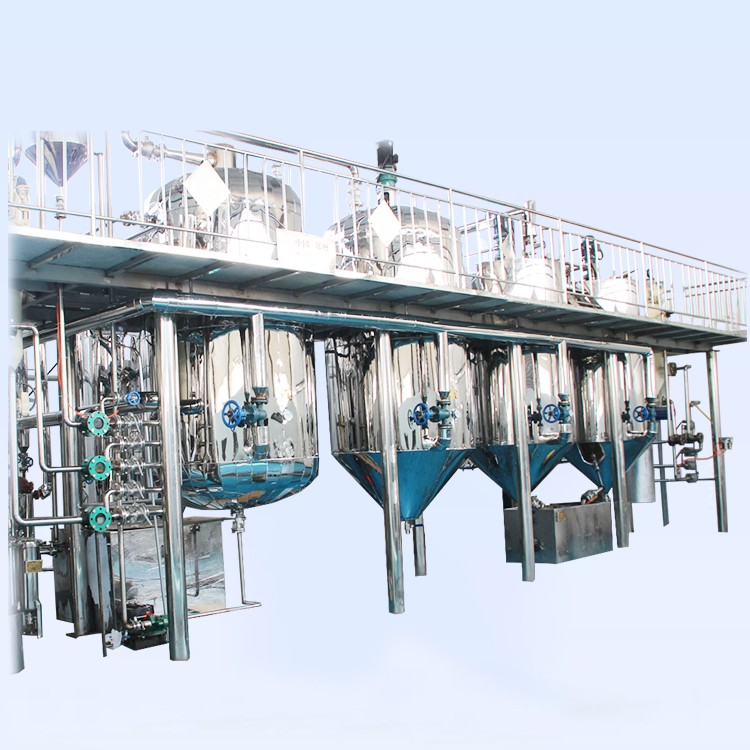

| 10-100T/D Cooking oil refinery plant |

| 1-500T/H oil material first cleaning, drying and storage section project. |

| We can design the project for customers’ demand. |

In the full continuous refining process, Henan Chengli machinery has absorbed advanced technology at home and abroad, combined with many years of practical experience, and adopted a unique degumming process. Under the premise of prolonging the reaction time of phosphoric acid and oil, by adding specific additives to maximize Limit the removal of phospholipids in the oil. The new white clay automatic quantitative system can make oil products more reliable, with less investment in the full vacuum closed refining process and good product quality. According to different oil types and different requirements for products, the best process route can be designed.